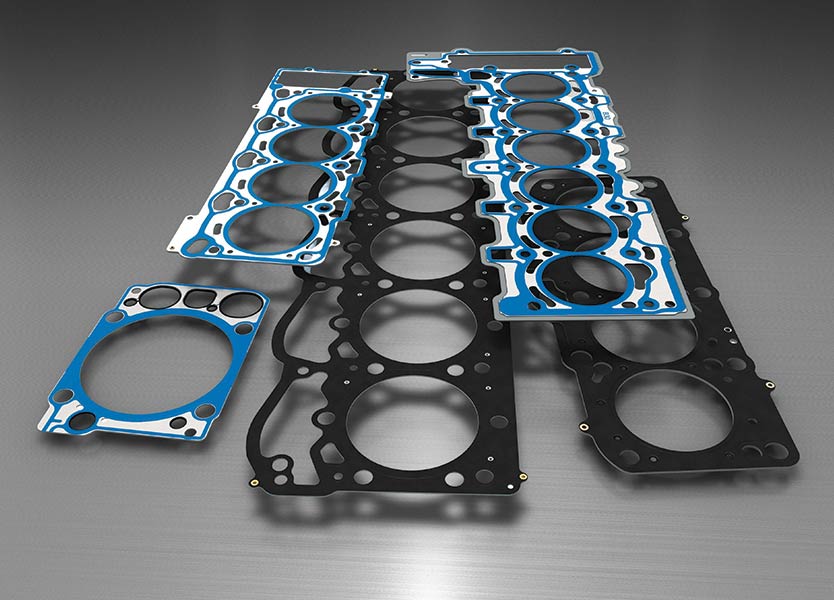

Better Performance from the Global Leader in Head Gasket Technology

PROBLEM

Increasingly high cylinder pressures and temperatures create a severe environment for head gaskets, which can lead to gasket failure—and the related expensive repairs and extended downtime.

SOLUTION

Victor Reinz multi-layer steel cylinder head gaskets provide superior sealing capabilities for the aftermarket repair environment.

Victor Reinz® supplies OE head gaskets to automotive and commercial vehicle manufacturers around the world. When you purchase a Victor Reinz gasket, you’ll get the same sealing power that the vehicle had when it was new.

- Secure, lasting macro- and micro-sealing

- Protection against fuel, oil, water, and anti-freeze

- Resistant to temperature differences commonly found in bi-metallic engines

- Excellent lateral stability

- Enhanced gasket architecture in critical sealing areas

- Effective transfer of bolt clamping forces

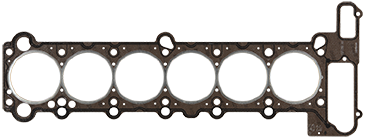

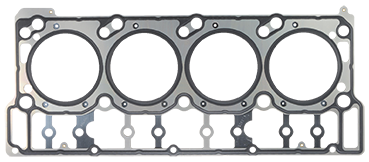

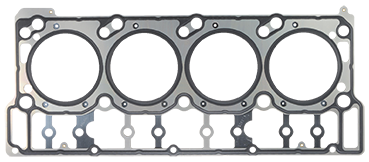

MLS Gaskets for Optimal Sealing

Multi-layer steel (MLS) head gaskets from Victor Reinz are manufactured using multiple layers of embossed stainless steel. Embossed beads and stoppers increase the clamping force around critical locations for macro-sealing, while elastomer coatings provide additional micro-sealing.

- Excellent durability and elasticity

- Gasket design accommodates singular engine architecture

- Extremely low compression set and torque loss

- The preferred design when combined with torque-to-yield head bolts

Nitroseal® Expanded Graphite Head Gaskets

Victor Reinz utilizes gasket designs that are appropriate for each generation of engines. As engine production shifted from heavy cast iron designs to lightweight bi-metal engines, expanded graphite head gaskets were a solution to the new sealing challenge.

- Accommodate head motion due to thermal expansion differences in cast iron engine blocks and aluminum cylinder heads

- Reduce torque loss

- Expanded graphite is temperature-resistant and conformable to less-than-ideal surface finishes

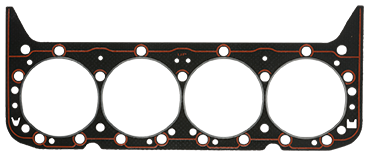

Composite Head Gaskets from Victor Reinz

The classic compressible, composite head gasket is generally specified for older applications. These head gaskets feature coatings that increase micro-sealing and prevent the gasket from swelling when it comes in contact with liquids.

- Excellent choice for traditional cast-iron engines

- Additional elements, such as coatings, saturants, and silk-screened elastomeric sealing beads, enhance fluid sealing

- Conformable to less-than-ideal surface finishes

| Make | Vehicle | Cyl. | Liters (L) | Year | Victor Reinz Set # | Manifold Gasket Set |

|---|---|---|---|---|---|---|

| BMW | Car | L6 | 2.5, 2.8L | 1991-1998 | 61-31940-00 | |

| Ford | Truck | V8 | 6.0L | 2003-2010 | 61-10405-00 | |

| Ford | Truck | V8 | 6.0L | 2003-2010 | 61-10409-00 | |

| FCA, Mitsubishi | Car & Truck | V6 | 3.7L | 2002-2012 | 61-10376-00 | |

| GM | Car & Truck | V8 | 4.3, 4.6, 4.9, 5.0, 5.3, 5.4, 5.7L | 1955-2002 | 61-10319-00 | |

| GM | Truck | V8 | 6.6L | 2001-2016 | 61-36465-20 | |

| GM | Car & Truck | V8 | 6.0, 6.2L | 2001-2016 | 61-36545-00 | |

| GM, Isuzu, Saab | Car & Truck | V8 | 4.8, 5.3, 5.7L | 1997-2015 | 61-10648-00 |

|

| Subaru | Car & Truck | H4 | 2.2, 2.5L | 1998-2011 | 61-10724-00 | |

| Subaru | Car | H4 | 2.5L | 1999-2011 | 61-53905-00 |

Get the Cylinder Head Gaskets OE Manufacturers Rely On

Victor Reinz gaskets are now supplied directly into aftermarket distribution channels by their manufacturer—Dana Incorporated. To find out where to buy Victor Reinz gaskets, check out our streamlined ecommerce and parts locator platform DanaAftermarket.com, or visit one of our Distribution Partners below.